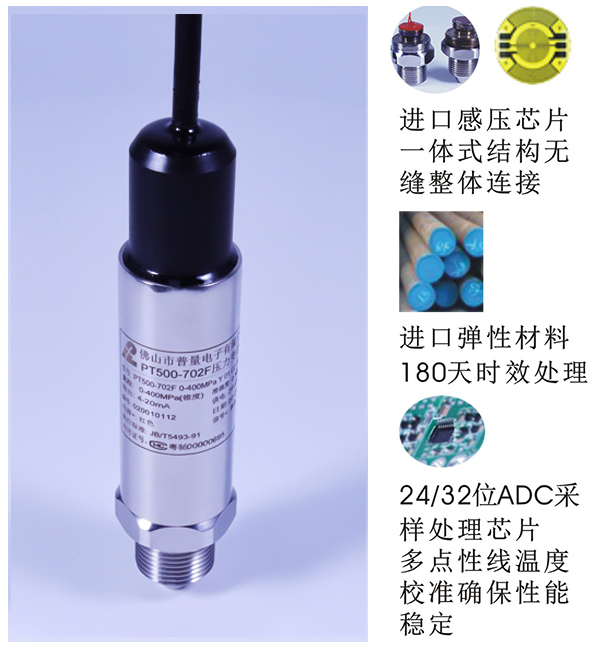

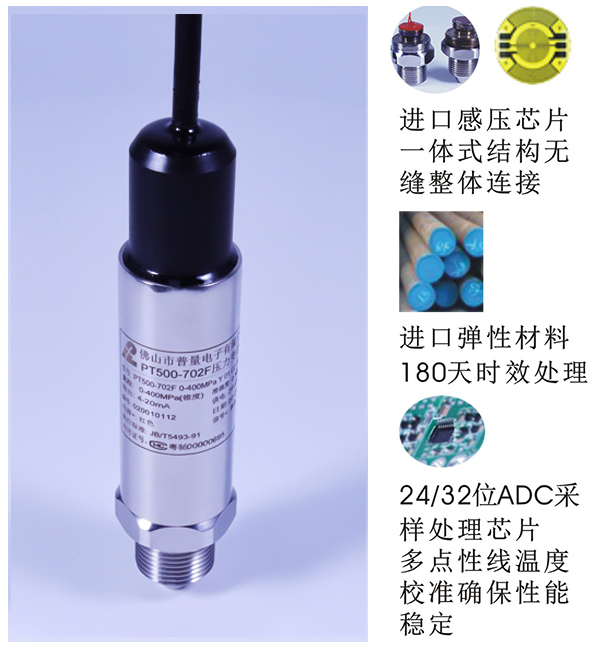

产品优势:

芯 片:

采用进口感压芯片;选进的贴片工艺,具有零点、满量程补偿、温度补偿;

应变计芯体,高强度弹性形变感压材料,配有温度补偿,具有抗冲击、耐疲劳性能优势;

微机械加工工艺,一体化结构设计、整体弹性材料,无焊工艺,受压1000MPA不会破裂,确保产品的安全性;

信号处理及输出:

24位ADC采样处理芯片;

DSP数字信号调理算法;

多点性线温度校准;

电压电流过载保护;

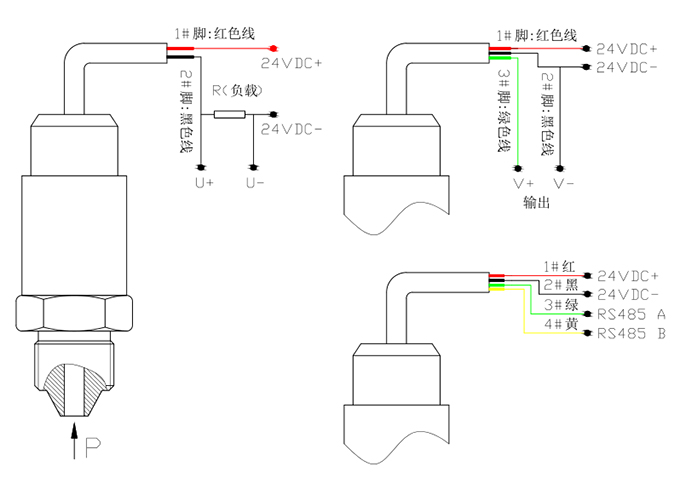

标准工业信号输出:4-20mA(二线制),0-20mA(三线制),0-5VDC,0-10VDC,0.5-4.5VDC(三线制);

数字通讯信号输出:RS485-RTU、超低功耗RS485-RTU

采用先进的32bit微处理器和24bit ADC

传输协议采用通用的MODBUS-RTU协议

支持波特率:1200~57600bps,校验位:NONE、ODD、EVEN

支持用户二次校准、清零、反清零、恢复出厂等操作

支持11种单位切换,支持浮点型、整型、百分比、格式化输出

采集间隔0~43200秒(12小时)可设,既可连续采集,满足高速采集的场合,也可单次触发采集,最大限度降低功耗

结 构:

结构小巧、全封焊结构、抗冲击、耐疲劳、可靠性高、多种过程连接方式;

过程连接材料,304,四种密封方式可选:锥度密封、端面密封、弧面密封、球面密封;

电气连接:IP68全密封结构引线,防水防潮,可水下、室外安装使用;

配套标准四芯屏蔽电缆;

应用:

大型液压机械,液压站的压力测量;

水刀机,陶瓷线割机压力测量与控制;

液压系统管道及液压设备压力测量控制;

室内外高压水泵等设备的压力测量与控制;

应用领域:

-

油压系统

-

陶瓷切割

-

水刀机设备

-

石油管道

-

高压水泵

-

液压设备

订购注意事项

PT500-702F产品订购注意事项

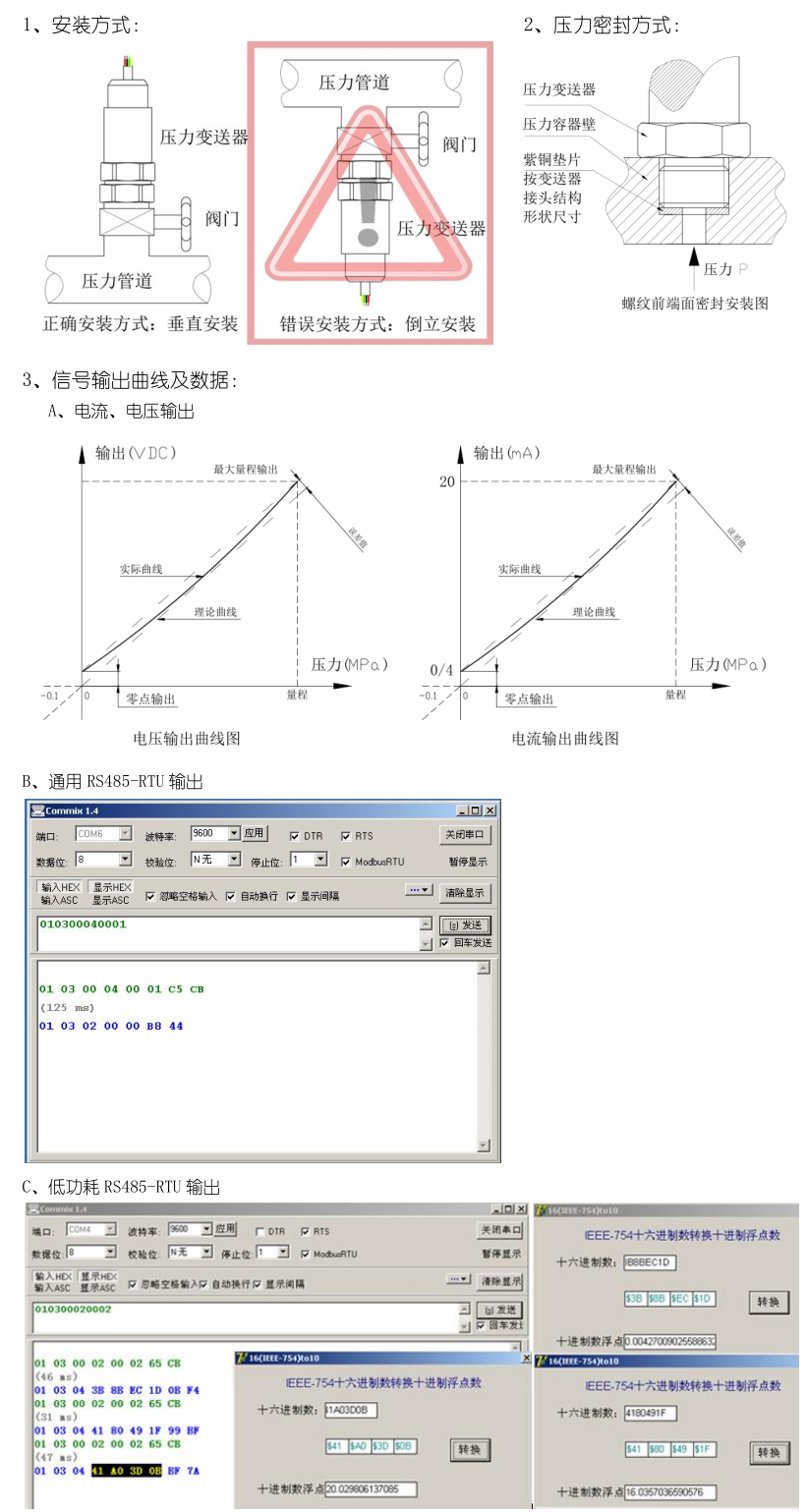

1、产品量程选择:

为了使产品精度、寿命、稳定性等功能达到最佳效果,产品的量程选 择参照以下公式计算:

量程 = 系统最大压力 X (1.2-1.5)倍;

产品的实际测量压力范围,应该在量程范围的15%-80%;

2、产品供电及输出:

供电范围的选择按产品的个输出规格确定:

常规4-20mA/0-20mA、0-5V/10V输出,直流12-30VDC供电;

通用RS485-RTU输出,直流12-30VDC供电;

0.5-4.5VDC输出,直流5VDC;

低功耗RS485-RTU输出,直流3.1-6.1VDC;

RS485-RTU输出时,请先了解通讯协议;

3、用户要了解产品的测量介质特性:

介质规格、介质温度、介质纯度(是否含有杂质或颗粒等);

4、用户要了解产品的安装环境及安装方式:

室内或室外安装;

环境温度;

要求的密封等级;

设备的振动范围;

压力密封方式:锥度密封、端面密封、弧面密封、球面密封;

安装空间是否满足产品外形尺寸;

Precautions for ordering PT500-702 products

1. Product range selection:

In order to achieve the best effect of product accuracy, life, stability and other functions, the range selection of the product is calculated by referring to the following formula:

Range = x (1.2-1.5) times of the maximum system pressure;

The actual measuring pressure range of the product should be 15% - 80% of the range;

2. Product power supply and output:

The selection of power supply range is determined according to the output specifications of the product:

Conventional 4-20mA / 0-20mA, 0-5V / 10V output, DC 12-30vdc power supply;

General rs485-rtu output, DC 12-30vdc power supply;

0.5-4.5vdc output, DC 5VDC;

Low power rs485-rtu output, DC 3.1-6.1vdc;

When output rs485-rtu, please understand the communication protocol first;

3. The user should understand the measurement medium characteristics of the product:

Medium specification, medium temperature, medium purity (whether containing impurities or particles, etc.);

4. Users should understand the installation environment and installation method of the product:

Indoor or outdoor installation;

Ambient temperature;

Required sealing level;

Vibration range of equipment;

Pressure seal: taper seal, face seal, arc seal, spherical seal;

Whether the installation space meets the overall dimension of the product;