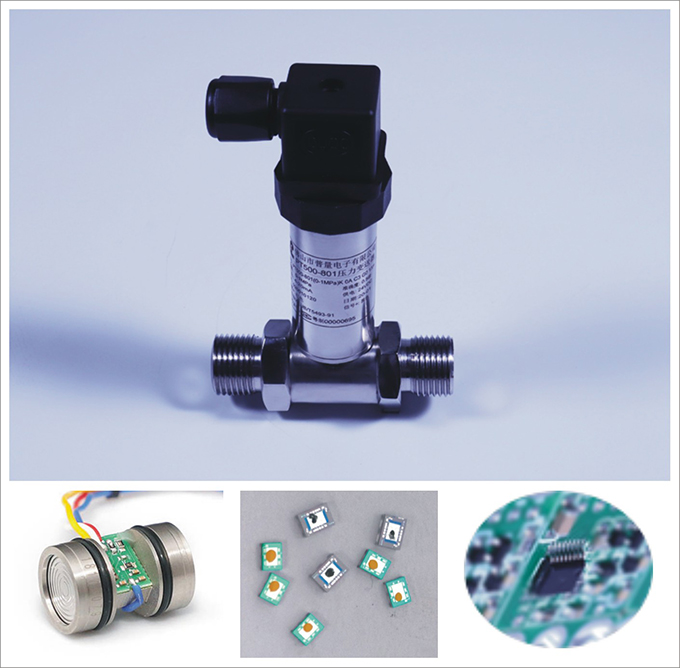

型号:PT500-801

进口型差压压力芯片,最大压差量程25MPa;静压最大70MPa;

304外壳材料,适用于测量液体、气体等介质差压;

高精度、稳定、数字标定调节、放大集成电路;

零点、满度,温补、线性补偿;

T字形结构,方便安装,M20X1.5/G1/2等过程连接;

常用关键字:

差压压力变送器 差压压力传感器

压差变送器 压差传感器

差压传感器 差压变送器

Model: PT500-801

Imported differential pressure chip with maximum differential pressure range of 25MPa;

The maximum static pressure is 70MPa;

304 shell material, suitable for measuring the differential pressure of liquid, gas and other media;

High precision, stable, digital calibration, regulation and amplification integrated circuit;

Zero point, full degree, temperature compensation, linear compensation;

A wide range of output signal types, 4-20mA / 0-20mA / 0-5V / 10V / rs485-rtu and low power consumption RS485;

T-shaped structure, easy to install, m20x1.5/g1/2 and other process connection;

Common keywords:

Differential pressure transducer

Differential pressure transducer

Differential pressure transducer

芯 片:

进口型差压压力芯片,最大压差量程25MPa;

静压最大70MPa;

3-5倍耐压,适用于测量液体、气体等介质差压测量;

零点、满度,温补、线性补偿;

高阻抗、高精度、高稳定性;

100万次使用寿命以上;

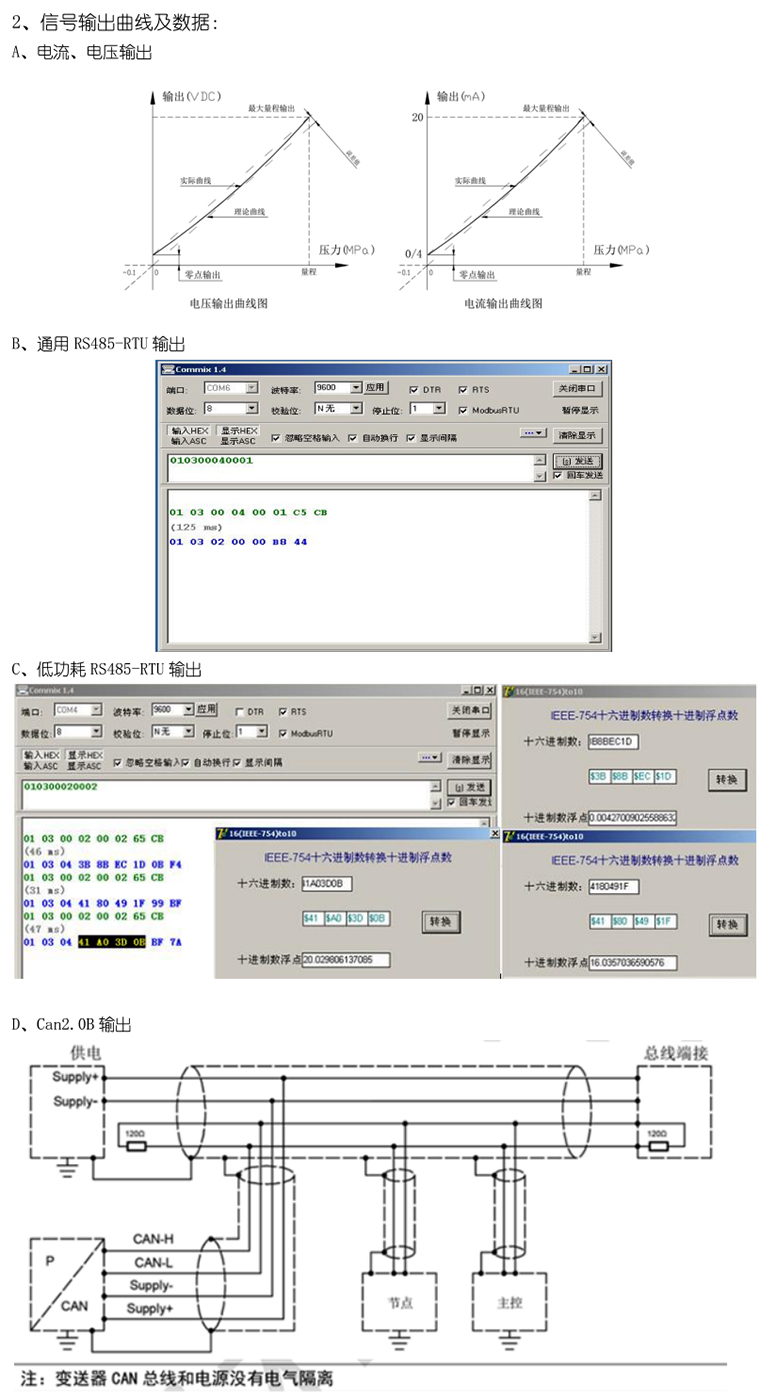

信号处理及输出:

24位ADC采样处理芯片;

DSP数字信号调理算法;

多点性线温度校准;

电压电流过载保护;

标准工业信号输出:4-20mA(二线制),0-20mA(三线制),0-5VDC,0-10VDC,0.5-4.5VDC(三线制);

数字通讯信号输出:RS485-RTU、超低功耗RS485-RTU

采用先进的32bit微处理器和24bit ADC

传输协议采用通用的MODBUS-RTU协议

支持波特率:1200~57600bps,校验位:NONE、ODD、EVEN

支持用户二次校准、清零、反清零、恢复出厂等操作

支持11种单位切换,支持浮点型、整型、百分比、格式化输出

采集间隔0~43200秒(12小时)可设,既可连续采集,满足高速采集的场合,也可单次触发采集,最大限度降低功耗

数字通讯信号输出:Can2.0B

测量速率:10...1000Hz 可设置,默认50Hz

CANopen输出内置 完整的 CANopen 协议栈,符合 DS301、DS404 规范,支持 LSS 服务,支持 BootLoader 在线 升级;

支持波特率(kbps)20/50/100/125/250(默认)/500/800/1000;支持特性 NMT/Heartbeat/SDO/PDO/LSS/Bootloader;CANopen 协议栈可以根据用户的要求进行定制;

J1939输出内置 J1939 协议栈,可以自由配置 PGN、SPN 以及 NAME,支持 BootLoader 在线升级;

支持波特率(kbps)20/50/100/125/250(默认)/500/800/1000

;支持特性PGN、SPN、NAME等自由配置

,J1939 协议栈可以根据用户的要求进行定制;

结 构:

T字形结构,方便安装,M20X1.5/G1/2等过程连接;

结构小,标准DIN43650 (赫斯曼)电气连接出线;

配套四/五芯屏蔽电缆;

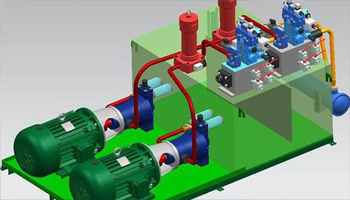

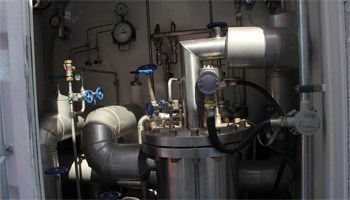

应 用:

液、气等介质的差压压力测量与监控;

城市管网、设备液压系统等差压压力测量与监控;

滤网、过滤器等前后差压压力测量与监控;

Chip:

Imported differential pressure chip, the maximum differential pressure range is 25MPa;

The maximum static pressure is 70MPa;

3-5 times withstand voltage, suitable for measuring differential pressure of liquid, gas and other media;

Zero, full, temperature compensation, linear compensation;

High impedance, high precision and high stability;

More than 1 million times of service life;

Signal processing and output:

24 bit ADC sampling and processing chip;

DSP digital signal conditioning algorithm;

Multipoint linear temperature calibration;

Voltage and current overload protection;

Standard industrial signal output: 4-20mA (two-wire system), 0-20mA (three wire system), 0-5vdc, 0-10vdc, 0.5-4.5vdc (three wire system);

Digital communication signal output: rs485-rtu, ultra-low power rs485-rtu

Advanced 32 bit microprocessor and 24 bit ADC are adopted

The transmission protocol is MODBUS-RTU

Support baud rate: 1200 ~ 57600bps, check bits: none, odd, even

Support the user's secondary calibration, reset, anti reset, restore factory operations

Support 11 kinds of units switching, support floating point, integer, percentage, formatted output

The acquisition interval of 0 ~ 43200 seconds (12 hours) can be set, which can not only meet the needs of high-speed acquisition, but also trigger acquisition once to minimize power consumption

Digital communication signal output: CAN2.0B

Measurement rate: 10... 1000Hz can be set, the default is 50 Hz

CANopen output built-in complete CANopen protocol stack, in line with ds301, ds404 specifications, support LSS services, support bootloader online upgrade;

Support baud rate (kbps) 20 / 50 / 100 / 125 / 250 (default) / 500 / 800 / 1000; support features of NMT / heartbeat / SDO / PDO / LSS / bootloader; CANopen protocol stack can be customized according to user requirements;

J1939 output has built-in J1939 protocol stack. PGN, SPN and name can be configured freely, and bootloader online upgrade is supported;

Support baud rate (kbps) 20 / 50 / 100 / 125 / 250 (default) / 500 / 800 / 1000; support free configuration of features such as PGN, SPN and name

The J1939 protocol stack can be customized according to the user's requirements;

Structure:

T-shaped structure, easy to install, m20x1.5/g1/2 process connection;

Small structure, standard din43650 (hesman) electrical connection line;

Supporting four / five core shielded cable;

Application:

Differential pressure measurement and monitoring of liquid, gas and other media;

Differential pressure measurement and monitoring of urban pipe network and equipment hydraulic system;

Differential pressure measurement and monitoring before and after filter screen, filter, etc;

智慧城市

蒸汽供给系统

油压系统

送风系统

石油管道

供气系统