产品优势:

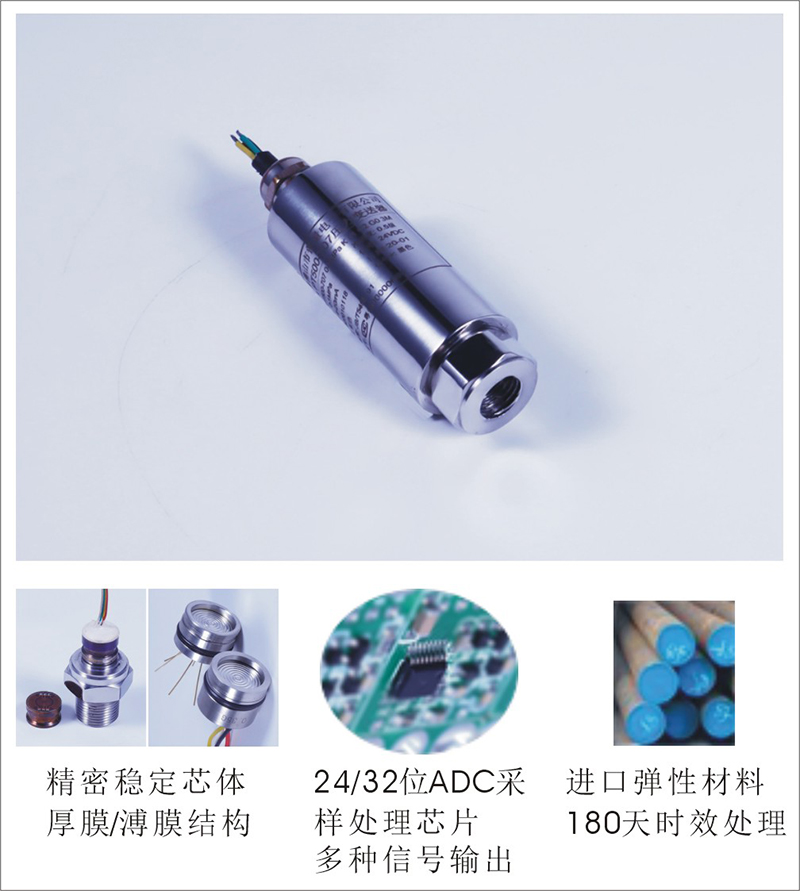

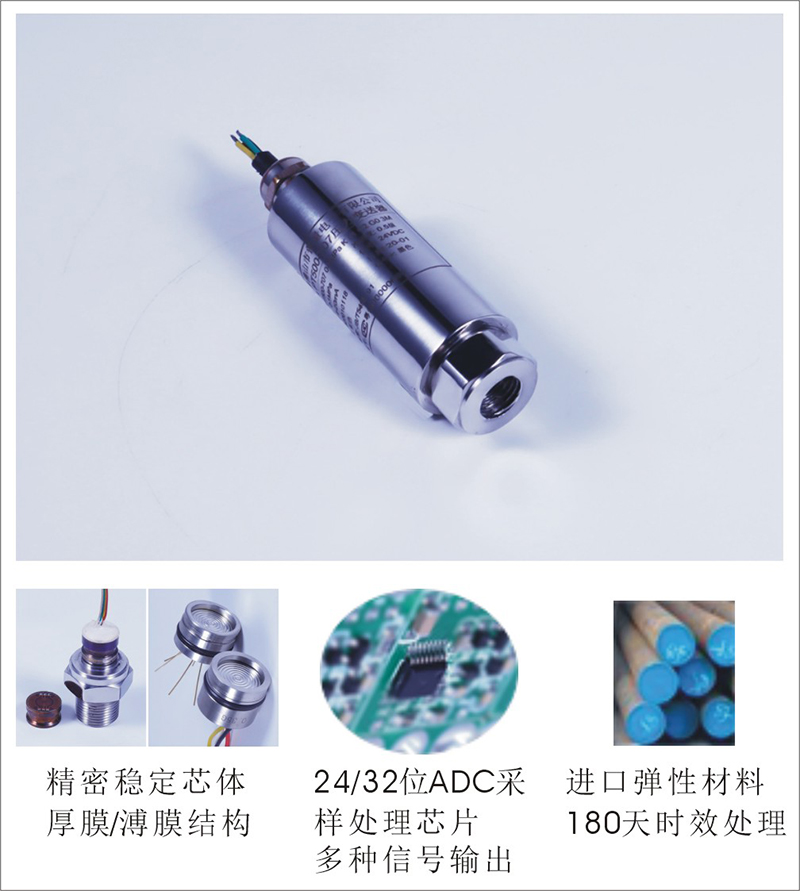

型号:PT500-707

精密稳定压力芯体;

冷媒介质(空调、冷库等)过程连接结构设计;

不锈钢过程连接,7/16-20NUF标准螺纹;

抗疲劳、耐冲击、良好的重复性能;

可替代同类型国外产品;

常用关键字:

冷媒压力变送器 冷媒压力传感器

空调压力变送器 空调压力传感器

Model: PT500-707

Precision stable pressure core body;

Process connection structure design of refrigerant medium (air conditioning, cold storage, etc.);

Stainless steel process connection, 7 / 16-20nuf standard thread;

Fatigue resistance, impact resistance and good repeatability;

It can replace the same type of foreign products;

Common keywords:

Refrigerant pressure transmitter refrigerant pressure sensor

Air conditioning pressure transmitter air conditioning pressure sensor

芯 片:

采用精密稳定感压芯片;选进的贴片工艺;

小量程芯片:充油硅芯片;

大量程芯片:压阻式厚膜芯片;

零点、满度,温补、线性补偿;

高阻抗、高精度、高稳定性;

100万次使用寿命以上;

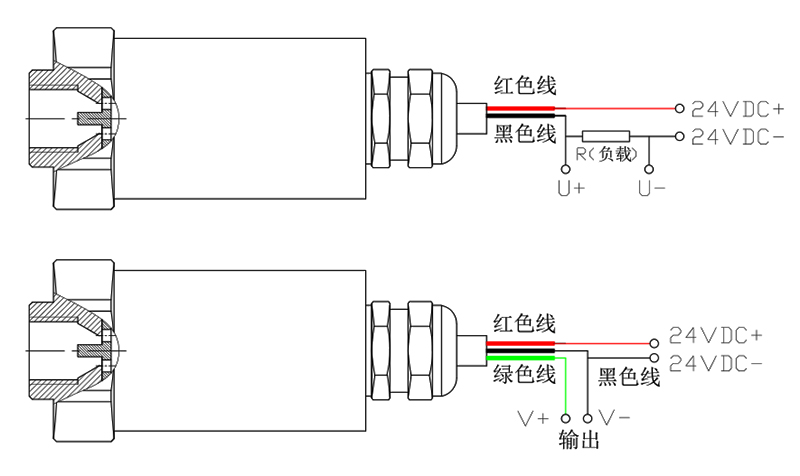

信号处理及输出:

24位ADC采样处理芯片;

DSP数字信号调理算法;

多点性线温度校准;

电压电流过载保护;

标准工业信号输出:4-20mA(二线制),0-20mA(三线制),0-5VDC,0-10VDC,0.5-4.5VDC(三线制);

数字通讯信号输出:RS485-RTU、超低功耗RS485-RTU

采用先进的32bit微处理器和24bit ADC

传输协议采用通用的MODBUS-RTU协议

支持波特率:1200~57600bps,校验位:NONE、ODD、EVEN

支持用户二次校准、清零、反清零、恢复出厂等操作

支持11种单位切换,支持浮点型、整型、百分比、格式化输出

采集间隔0~43200秒(12小时)可设,既可连续采集,满足高速采集的场合,也可单次触发采集,最大限度降低功耗

数字通讯信号输出:Can2.0B

测量速率:10...1000Hz 可设置,默认 50Hz

CANopen输出内置 完整的 CANopen 协议栈,符合 DS301、DS404 规范,支持 LSS 服务,支持 BootLoader 在线 升级;

支持波特率(kbps)20/50/100/125/250(默认)/500/800/1000;支持特性 NMT/Heartbeat/SDO/PDO/LSS/Bootloader;CANopen 协议栈可以根据用户的要求进行定制;

J1939输出内置 J1939 协议栈,可以自由配置 PGN、SPN 以及 NAME,支持 BootLoader 在线升级;支持波特率(kbps)20/50/100/125/250(默认)/500/800/1000;支持特性PGN、SPN、NAME等自由配置,J1939 协议栈可以根据用户的要求进行定制;

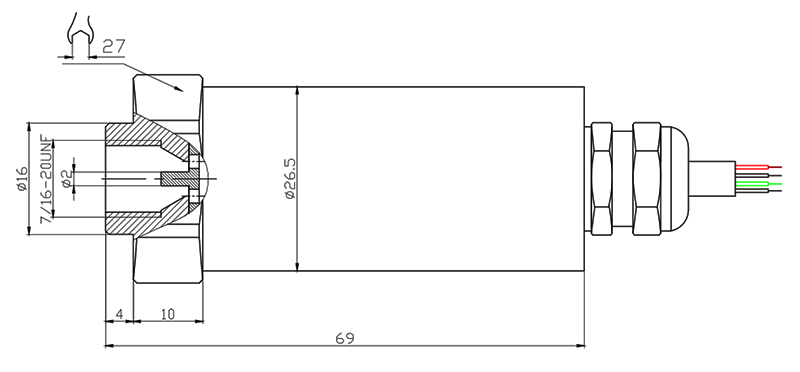

结 构:

深度氩弧焊接,连接弹性材料与过程接头,强度高,抗冲击,耐疲劳;

冷媒介质(空调、冷库等)过程连接结构设计;

不锈钢过程连接,7/16-20NUF标准螺纹;

抗疲劳、耐冲击、良好的重复性能;

过程连接材料:304或316;

应 用:

空调、冷库等冷媒介质的压力测量与控制;

楼宇/工业/电力/石油/自动化等领域的设备压力测量;

Chip:

It adopts precision stable pressure sensitive chip and selective placement technology;

Small range chip: oil filled silicon chip;

Large range chip: piezoresistive thick film chip;

Zero point, fullness, temperature compensation and linear compensation;

High impedance, high precision and high stability;

More than 1 million times of service life;

Signal processing and output:

24 bit ADC sampling and processing chip;

DSP digital signal conditioning algorithm;

Multipoint linear temperature calibration;

Voltage and current overload protection;

Standard industrial signal output: 4-20mA (two-wire system), 0-20mA (three wire system), 0-5vdc, 0-10vdc, 0.5-4.5vdc (three wire system);

Digital communication signal output: rs485-rtu, ultra-low power rs485-rtu

Advanced 32 bit microprocessor and 24 bit ADC are adopted

The transmission protocol is MODBUS-RTU

Support baud rate: 1200 ~ 57600bps, check bits: none, odd, even

Support the user's secondary calibration, reset, anti reset, restore factory operations

Support 11 kinds of units switching, support floating point, integer, percentage, formatted output

The acquisition interval of 0 ~ 43200 seconds (12 hours) can be set, which can not only meet the needs of high-speed acquisition, but also trigger acquisition once to minimize power consumption

Digital communication signal output: CAN2.0B

Measurement rate: 10... 1000Hz can be set, the default is 50 Hz

CANopen output built-in complete CANopen protocol stack, in line with ds301, ds404 specifications, support LSS services, support bootloader online upgrade;

Support baud rate (kbps) 20 / 50 / 100 / 125 / 250 (default) / 500 / 800 / 1000; support features of NMT / heartbeat / SDO / PDO / LSS / bootloader; CANopen protocol stack can be customized according to user requirements;

J1939 output has built-in J1939 protocol stack. PGN, SPN and name can be configured freely, and bootloader online upgrade is supported;

Support baud rate (kbps) 20 / 50 / 100 / 125 / 250 (default) / 500 / 800 / 1000; support free configuration of features such as PGN, SPN and name

The J1939 protocol stack can be customized according to the user's requirements;

Structure:

Deep argon arc welding, connecting elastic material and process joint, high strength, impact resistance and fatigue resistance;

Process connection structure design of refrigerant medium (air conditioning, cold storage, etc.);

Stainless steel process connection, 7 / 16-20nuf standard thread;

Fatigue resistance, impact resistance and good repeatability;

Process connection material: 304 or 316;

Application:

Pressure measurement and control of air conditioning, cold storage and other refrigerant media;

Pressure measurement of equipment in building / industry / power / Petroleum / automation fields;

应用领域:

-

中央空调机组

-

空压机组

-

供气系统

-

供气管道

-

给水设备

订购注意事项

PT500-707产品订购注意事项

1、产品量程选择:

为了使产品精度、寿命、稳定性等功能达到最佳效果,产品的量程选择参照以下公式计算:

量程 = 系统最大压力 X (1.2-1.5)倍;

产品的实际测量压力范围,应该在量程范围的15%-80%;

2、产品供电及输出:

供电范围的选择按产品的个输出规格确定:

常规4-20mA/0-20mA、0-5V/10V输出,直流12-30VDC供电;

通用RS485-RTU输出,直流12-30VDC供电;

0.5-4.5VDC输出,直流5VDC;

低功耗输出供电范围:3.6VDC(3-5VDC)

3、用户要了解产品的测量介质特性:

介质规格、介质温度、介质纯度(是否含有杂质或颗粒等);

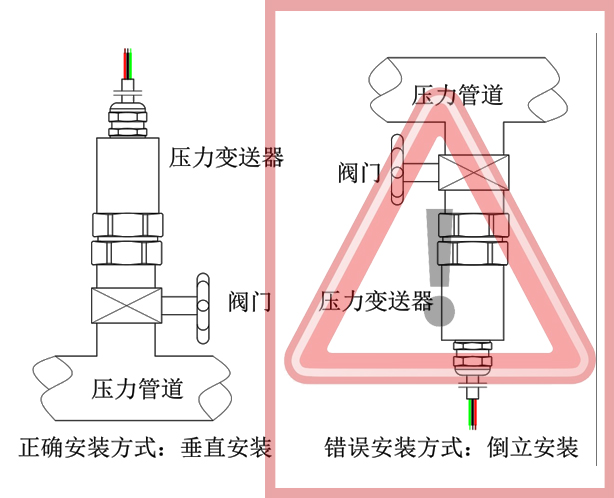

4、用户要了解产品的安装环境及安装方式:

隔爆防护等级能否满足现场工况要求;

室内或室外安装;

环境温度;

要求的密封等级;

设备的振动范围;

安装方式:螺纹、法兰、特殊结构;

安装空间是否满足产品外形尺寸;

Precautions for ordering PT500-707 products

1. Product range selection:

In order to achieve the best effect of product accuracy, life, stability and other functions, the range selection of the product is calculated by referring to the

following formula:

Range = x (1.2-1.5) times of the maximum system pressure;

The actual measuring pressure range of the product should be 15% - 80% of the range;

2. Product power supply and output:

The selection of power supply range is determined according to the output specifications of the product:

Conventional 4-20mA / 0-20mA, 0-5V / 10V output, DC 12-30vdc power supply;

General rs485-rtu output, DC 12-30vdc power supply;

0.5-4.5vdc output, DC 5VDC;

Low power output power supply range: 3.6vdc (3-5vdc)

3. The user should understand the measurement medium characteristics of the product:

Medium specification, medium temperature, medium purity (whether containing impurities or particles, etc.);

4. Users should understand the installation environment and installation method of the product:

Whether the flameproof protection level can meet the requirements of field conditions;

Indoor or outdoor installation;

Ambient temperature;

Required sealing level;

Vibration range of equipment;

Installation method: thread, flange, special structure;

Whether the installation space meets the overall dimension of the product;